About Us

The Oldest, Largest, & Last

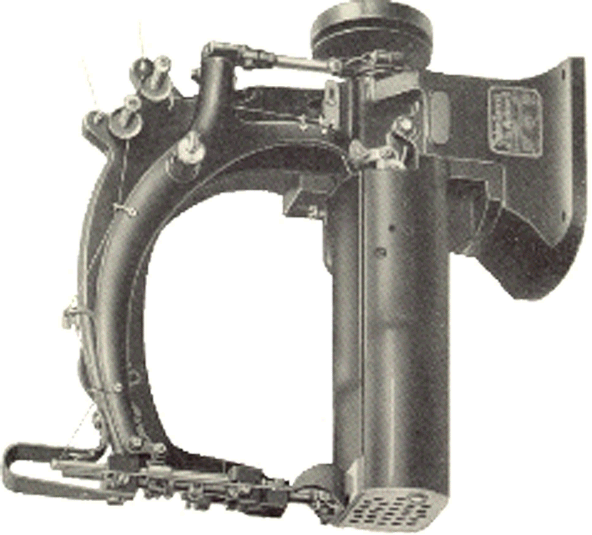

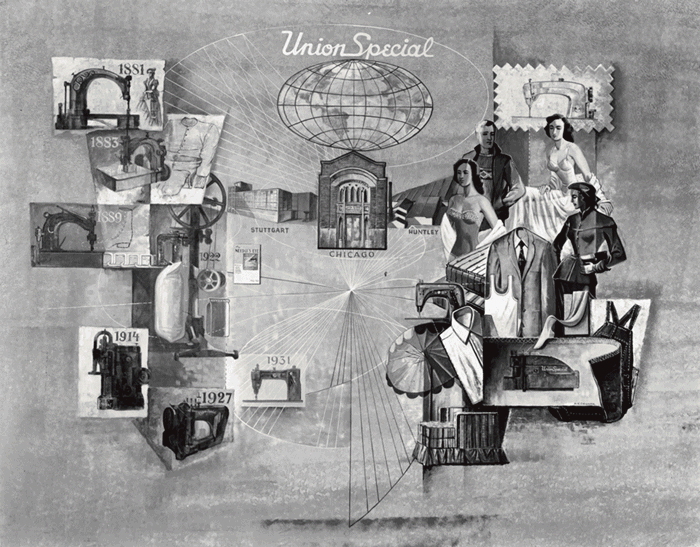

Established in 1881, Union Special is the oldest, largest, and last industrial sewing machine company, making bag closing, bag making, carpet, and geotextile machines. We produce the Finest Quality sewing machines and parts, from casting to finished products, under one roof.

Union Special continues to provide genuine parts to support the vast array and volume of Union Special brand machines in the market today.

Finest Quality

Product & Services

Union Special’s large variety of state-of-the-art manufacturing equipment is operated by people who have set an industry standard for excellence. CNC equipment such as Machining Centers, Turning Centers, and Grinding Centers, as well as Precision Investment Casting, , Powder Paint application, and In-House Assembly, provide finished machines and parts that are second to none in quality, performance and longevity.

Union Special’s strength lies in its ‘Finest Quality’ and the people who make it happen. Our experienced sales and technical service staff is poised to provide unmatched customer support.

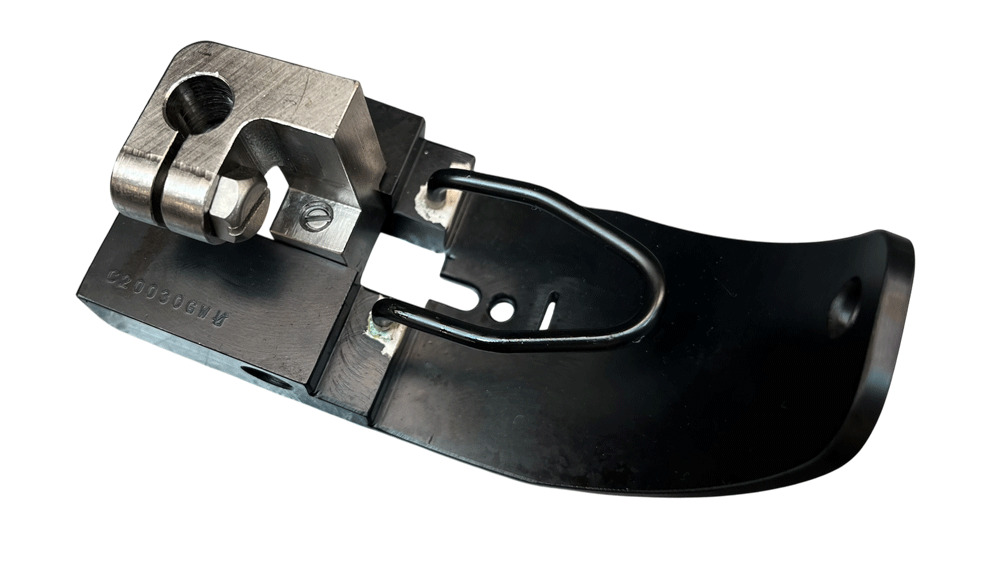

Products include various sewing machines and parts for the non- apparel industry. Bag Making, Bag Closing, Carpet Overedging, and Geosynthetics are the main industries we service.

A full line of Union Special sewing machine parts is also manufactured and supplied worldwide.

Step into History

The “Big H” – History of theUnion Special Huntley Facility

In early 1948, “Union Special Machine Company” (as it was then called) purchased the “Fencil Plant,” a manufacturer of gaskets for machinery, in Huntley, Illinois.

At that time, Union Special Machine Company had its main office and manufacturing in Chicago and a manufacturing facility in Germany. The Fencil plant covered 44,000 square feet, with additional land available for future expansion. It was purchased less than two years after the addition of three new manufacturing floors to the company’s main factory in Chicago. This step was taken to meet the high demand for modern sewing equipment.

The Huntley Plant started production on May 3, 1948. It soon became a full production facility and performed all aspects of machining and painting parts. The plant also assembled some sewing machines.

The machining of parts was performed on the latest 1940s state-of-the-art machining equipment such as the drill press, milling machine, Natco multi-spindle drilling machines, and surface grinders. The turning work was performed on hand or automatic screw machine lathes.

1950s—Four building additions were made at Huntley, totaling over 165,000 square feet of manufacturing space. All assembly lines had moved from Chicago and were now part of the Huntley plant.

1960s – Union Special Machine Company purchased a Numerical Control Milling and Drilling machine used in the production machine shop. Union Special was one of the first manufacturers in the Midwest to purchase this type of machine.

The “Big H” plant

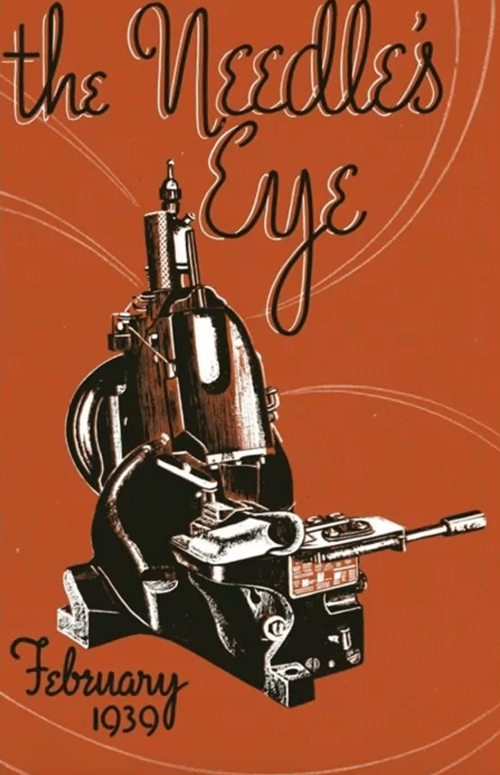

The one-millionth machine, a Class 39500 Union Special® sewing machine, was produced at the “Big H” plant in 1968. Excerpted from the April 1968 issue of The Needle’s Eye – “On hand to mark the occasion were manufacturing officials for the company, headed by William S. North, president. In addressing those present, Mr. North emphasized that credit for the company’s expansion and growth is directly attributable to the quality built into each machine and pointed to the fact that Union Special has more than doubled its manufacturing capacity in the past ten years.”

Three more additions were made to the Huntley facility, bringing the total manufacturing space to over 282,000 square feet.

The 1970s—In the early seventies, a new Technical Training Center was built on the Huntley property, and the company changed its name from “Union Special Machine Company” to “Union Special Corporation.” Also, during this time, two more building additions brought the Huntley plant to over 376,000 square feet.

1980s—Union Special consolidated the Chicago manufacturing operation to the Huntley plant, which required the tenth addition and expanded the manufacturing building to its current size of 418,000 square feet. The 1980s also brought about Computer-Aided Design (CAD) at Union Special. CAD gave the design engineers a tool for designing and testing new product designs on a computer before making a part in the factory. In 1988, Union Special started the “Employee Involvement Program.”

1990s – Union Special received many awards for its employee involvement activities. In 1995, the company’s manufacturing personnel team received first place in the State of Illinois Manufacturers Association competition for Small Group Problem Solving Teams. “Rapid Prototyping”, another new technology, was introduced to Union Special. Rapid Prototyping provides the capability to produce prototypes quickly and/or small production runs of cast parts directly from an electronic data file from CAD and a Sanders Rapid Prototyping machine.

2000s & Today – Union Special has been in the Huntley facility for over sixty years.

Our approach

In 2003, the company added a state-of-the-art vertical machining center to manufacture machine frames. The company still produces the majority of its parts in Huntley, including all loopers and spreaders. The company does its own heat treatment, frame manufacturing, investment casting, CNC, stamping, and machine assembly.

Union Special machines and parts are built to last by employees whose average years of service with the company are 27 years! The company’s American owners have all been with the company for more than 30 years.

Many of the machines built at the ‘Big H’ in the last 60 years, even those from the 1950s, 60s, and 70s, are still being used today all over the world.

When they say, “They don’t make them like that anymore,” they are not talking about Union Special because WE STILL DO!