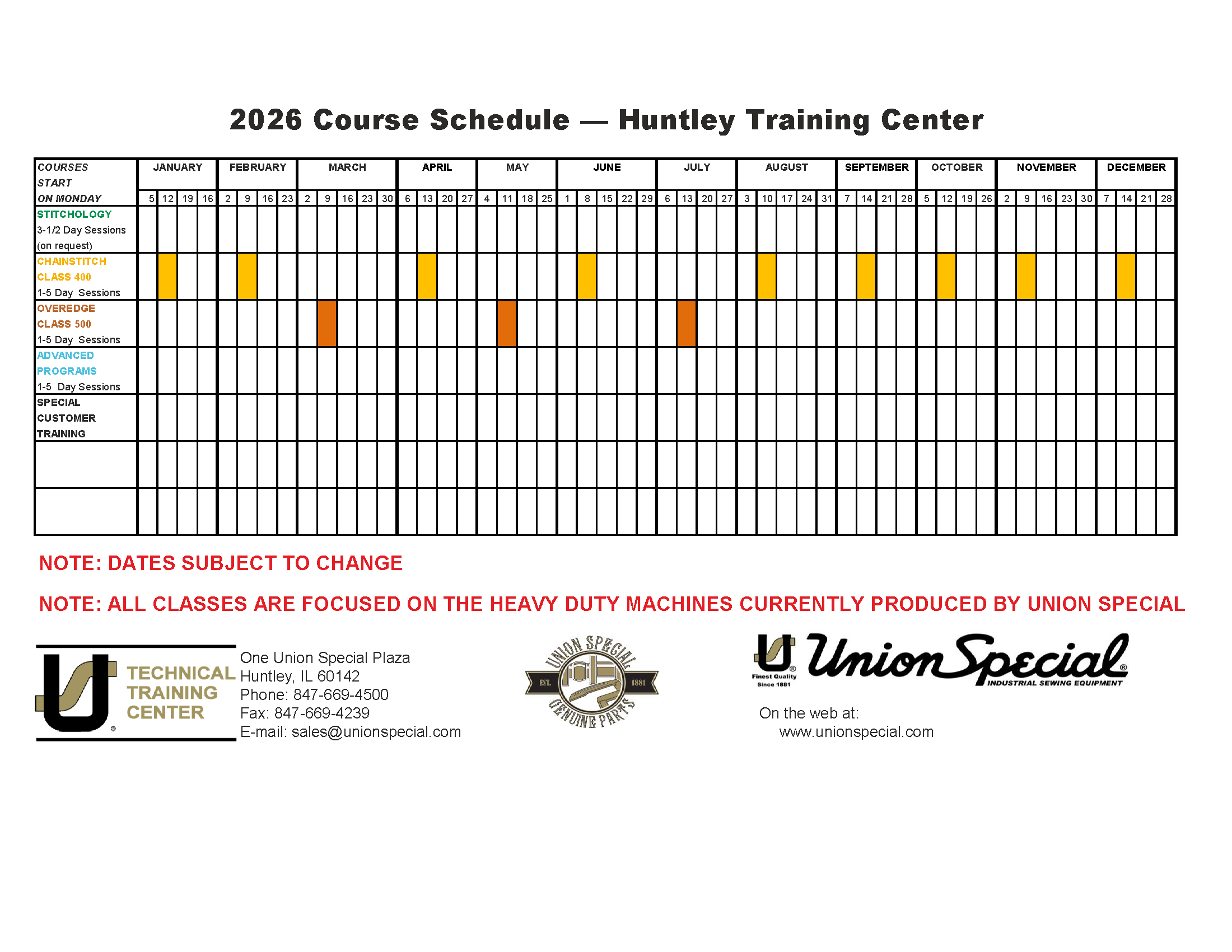

Training & Programs

Are You Providing Your Employees With All The Tools They Need?

Hammers and screwdrivers are not enough. And on-the-job experience is acquired at your production’s expense. Your mechanic needs professional training to help you maximize plant productivity.

Union Special’s Technical Training Center offers the hands-on courses that will give your mechanic the skills to quickly diagnose and remedy sewing problems. As a result, your equipment is back on-line faster, operating at maximum output, and with the quality you need to stay competitive.

“There is something for everyone”. For both the novice and the experienced, TTC courses are open not only to mechanics, but also to supervisors, engineers, management, QC, Sales, and executive personnel. The courses are ideal for anyone who desires to further their knowledge and understanding of stitches, seams, and the machines that produce them.

You can find a complete list of programs offered below!

-

Training covers Class 400 Multi-thread Chainstitch and Bottom Coverstitch machines. (Machines with Loopers)

Classes can run from 1 to 5 days

The Chainstitch class 400 covers the various machines that utilize sewing machine needles and loopers for forming the stitch on the bottom of the material. Emphasis is put on the timings and major adjustments to the sewing area as well as, thread controls, tension adjustments, maintenance, trouble shooting and sewing techniques.

Included in this class are:

✔ Single and multi needle machines

✔ Looper in line of feed machines

✔ Looper across the line of feed machines

✔ Feed off the Arm machines

✔ Cylinder bed machines

✔ Long arm machines (Samson)

✔ Top and bottom feed machines

✔ Differential feed machines

✔ Portable Bag and Geo machines

✔ Heavy-duty Bag and Geo machines

Approximately 20% of the course is spent in the classroom, where students are trained on basic stitch types, needles, threads, the stitch formation, and the machine adjusting and trouble shooting specifications.

Approximately 80% of the course is spent in the lab, where students learn to put to use the information learned in the classroom, as well as disassemble, assemble, adjust, sew-off and troubleshoot a particular machine style or class.

-

Training covers Class 500 Overedge and Safety Stitch machines. (Machines also called Sergers)

Classes can run from 1 to 5 days

The Overedge and Safety Stitch 500 class covers the various machines that utilize sewing machine needles, loopers and spreaders for forming the stitch over the edge of the material. Emphasis is put on the major timings, adjustments to the sewing area and material trimming knives as well as thread controls, tension adjustments, maintenance, trouble shooting and sewing techniques.

Included in this class are:

✔ One thread overedge machines

✔ Two thread overedge machines

✔ Three thread overedge machines

✔ Four thread overedge machines

✔ Four thread safety stitch machines

✔ Five thread safety stitch machines

Approximately 20% of the course is spent in the classroom, where students are trained on basic stitch types, needles, threads, the stitch formation, and the machine adjusting and trouble shooting specifications.

Approximately 80% of the course is spent in the lab, where students learn to put to use the information learned in the classroom, as well as disassemble, assemble, adjust, sew-off and troubleshoot a particular machine style or class.

Programs

Application For Enrollment

Tuition for 1-day programs: $600.00

Tuition for 2-day programs: $750.00

Tuition for 3-day programs: $900.00

Tuition for 4-day programs: $1050.00

Tuition for 5-day programs: $1,200.00

*Tuition is subject to change without notice.

For more information on TTC Training Contact:

Mike Faber

Email: mfaber@unionspecial.com

Phone: 847.669.4381